WHERE QUALITY MEETS INNOVATION

IN FISH AND SEAFOOD PROCESSING

ABOUT

In 1995, in Nīca on the Latvian Baltic Sea coast, the factory "Piejūra" ("By the sea") was established and on January 13, 1996 started operations with a hot-smoked, semi-finished fish production shop. Since then, the company has been in continuous development.

In 2003, the plant was upgraded to meet EU canning industry standards, and in 2009 "Piejūra" signed a contract with the Rural Support Service's Fishery Fund to co-finance renovation and purchase of equipment worth 1.5 million lats. In 2010, the plant was further modernized, becoming one of the most advanced fish processing facilities in the Baltics, continuously adapting to Latvian and EU requirements to ensure the highest product quality.

Piejūra's activities are driven by passion and a strong sense of environmental responsibility. Since 2011, the company has sourced electricity and heat from a nearby biogas power plant. In 2013, a further EUR 3 million was invested in equipment and renovation, enabling expansion into frozen breaded products.

Under ERAF project No. 1.2.1.1/16/A/004, the company received co-financing for research on using the co-extrusion method, resulting in a new product line of innovative items, including exported fish bite snacks. Together with the Kaliningrad institute Atlant-NIRO, research is also carried out on the use of by-products in new products with defined shelf life.

In 2018, an investment round brought in the development-focused NS Estate team, which took over the factory and continued its growth, launching various new products in cooperation with Latvian and international scientists. In 2022, the company installed 400 kW of solar panels, increasing its own green energy supply. Currently, a reconstruction project is underway to introduce fully automatic packaging of frozen products and additional electricity generation capacity. In parallel, in 2025 the company started a project to diversify production with new plant-based snack products.

.jpg)

Interested in collaboration, getting Amberfish or PL products from the factory? Contact our distributor

SFT SeafoodSERVICES

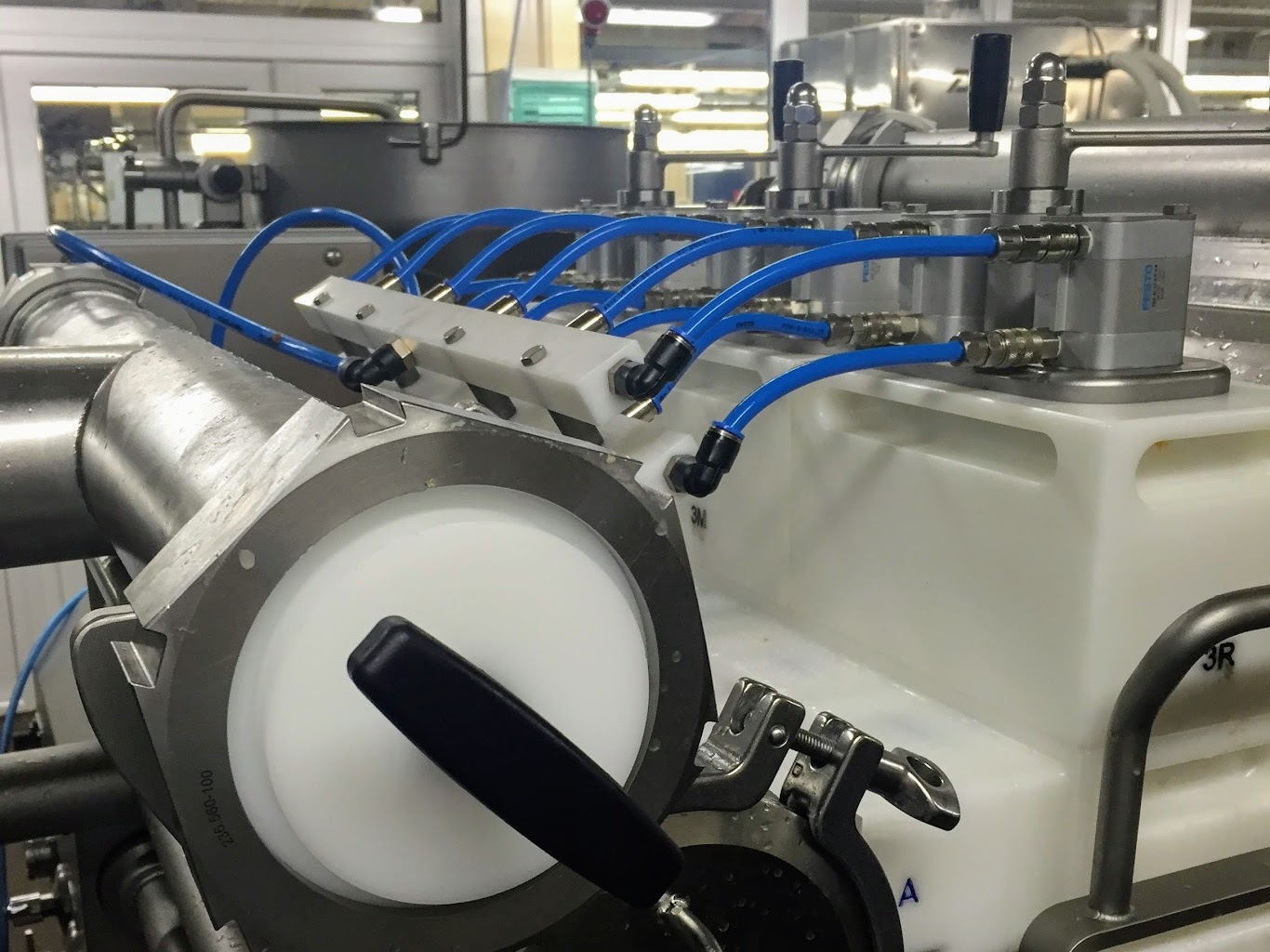

Forming and Co-extrusion Line

Advanced forming and co-extrusion line capable of producing non-standard shapes and innovative products. Our state-of-the-art co-extrusion technology allows for unique product development.

Equipped with a spiral freezer with capacity of 300 kg/h, ensuring rapid freezing and optimal product quality.

Canning

Our modern canning facility has a capacity of 1.8 million cans per month. We utilize state-of-the-art equipment and autoclaves to ensure the highest quality standards.

All quality tests are conducted on-site in our laboratory, guaranteeing product safety and excellence.

Interested in collaboration, getting Amberfish or PL products from the factory? Contact our distributor

SFT SeafoodPACKAGING

Metal cans

High-quality metal cans for long-term preservation

Glass jars

Premium glass jars for premium seafood products

Innovative canning

Modern packaging solutions for contemporary markets

Plastic trays

Convenient packaging for frozen products

Interested in collaboration, getting Amberfish or PL products from the factory? Contact our distributor

SFT SeafoodDEVELOPMENT PARTNERS

Our Projects

Innovative vegan cheese: development and integration of sustainable food solutions

Projekta Nr. 5.1.1.2.i.0/2/24/A/CFLA/003 JP-18 2025. gada 1. janvārī SIA "NS Estate" sadarbībā ar SIA "Latvijas Pārtikas kompetences centrs", kurš saskaņā ar Ministru kabineta 2024. gada 9. janvāra noteikumiem Nr. 32 "Latvijas Atveseļošanas un noturības mehānisma plāna 5.1. reformu un investīciju virziena "Produktivitātes paaugstināšana caur investīciju apjoma palielināšanu P&A" 5.1.1.r. reformas "Inovāciju pārvaldība un privāto P&A investīciju motivācija" 5.1.1.2.i. investīcijas "Atbalsta instruments pētniecībai un internacionalizācijai" otrās kārtas īstenošanas noteikumiem, īsteno pētniecības projektu "Inovatīvs vegānu siers: ilgtspējīgu pārtikas risinājumu izstrāde un integrācija". Projektu finansē Eiropas Savienība. Projekta ilgums: 01/2025 – 03/2026 Sasniegtais rezultāts 01/2025 – 03/2025 1.1 Produkta tekstūras un reoloģisko īpašību laboratorijas līmeņa validācija. Veikti laboratoriskie testi, lai analizētu siera un vegānu siera tekstūru, viskozitāti un noturību pret mehānisko iedarbību. 1.2 Formēšanas procesa optimizācija co-extrusion līnijā Testēti dažādi spiediena, temperatūras un masas parametri uz co-extrusion līnijas. 2.1 Panēšanas procesa izpēte un optimizācija Izmēģinātas dažādas panēšanas formulas un metodes uz vegānā produkta virsmas. Sasniegtais rezultāts 04/2025 – 06/2025 2.2 Temperatūras apstrādes ietekmes izpēte Izpētīta temperatūras apstrādes ietekme uz produkta tekstūru, garšu un panējuma stabilitāti, lai nodrošinātu produkta augstu kvalitāti. 2.3 Vēganā siera pielietošana "laša bumbiņas" produktā Tehnoloģiskā atskaite ar recepti un rekomendācijām vēganā siera pielietošanai laša bumbiņās. 2.4 Vēganā siera pielietošana krokešu veidā Izstrādāt vegānā siera krokešu 4 receptūras un tehnoloģiju, nodrošinot stabilu kvalitāti un noturīgu panējumu.

EMPLOYMENT

We are always looking for talented individuals to join our team. Please contact us by phone or use the form below to send your CV.

CONTACT

Head Office / Inquiries

SIA NS Estate

Reg/VAT: LV40103845006

Avoti, Nīca pagasts, Nīcas novads

Direct Lines

Send us a message

For inquiries, please call +371 26 781 636 or use the form below: